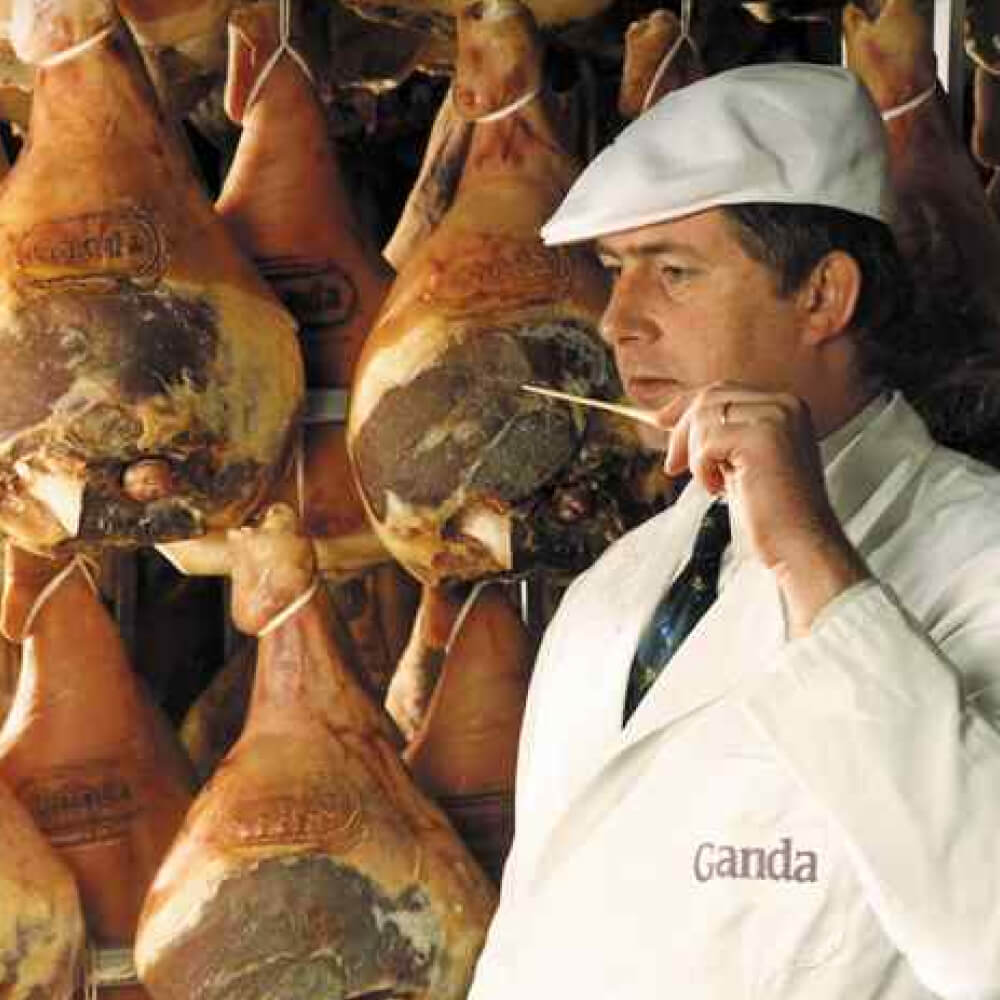

PURSUIT OF EXCELLENCE

Quality is not something that can be taken for granted. Striving for it requires a constant focus, right down to the smallest detail. Quality is not an empty promise; rather, it’s a guiding principle for our corporate philosophy. As is having a consistent approach, manifested first and foremost in producing a natural product according to eco-friendly production processes.

This artisanal approach is coupled with the use of modern technology. Ganda is always looking to participate in a wide range of scientific research projects (reducing the salt content in meat products, overall health, fatty acid composition, waste disposal, etc.) to ensure that the quality of Ganda Ham is preserved, while at the same time continuing to improve the production process.

Time never stands still here. Unless we stop to enjoy a piece of Ganda Ham.

GUARANTEED TRACEABILITY FROM FARM TO FORK

As early as 1992, Ganda started working on integrated quality management in a more structured manner. This was rewarded a year later, with Ganda becoming the very first Belgian company within the meat products sector to obtain ISO 9002 certification – a guarantee of officially recognised and thorough quality assurance systems. Even then, Ganda was already taking pig farmers to task in terms of traceability from farm to final product, a practice that has since become commonplace within the food sector. Consequently, we were awarded the BRC Global Standard for Food Safety, as well as the IFS Food Standard. Both standards are intended for private label product suppliers to retailers and have food safety and hygiene within the food processing sector as their main objective.

SELF-CHECKING

Self-checking is the set of measures taken by Ganda to ensure that all our products, throughout all stages of production, processing, and distribution (under our control), comply with the legal requirements on food safety, quality, and traceability. We use the ‘self-checking guide’, a document approved by the FASFC and drawn up by and for the industry with instructions on how to comply with legally imposed requirements for hygiene, traceability, and self-monitoring.

At least once a year, raw material suppliers are also subjected to a comprehensive evaluation according to a number of fixed criteria, which are then expressed in terms of objective figures (including delivery punctuality, quality, temperature, hygiene, returns, proper documentation, price, etc.).

Any complaints are examined for merit by the head of the department concerned. In consultation with any other people concerned, they will decide whether or not to accept the complaint, along with any immediate actions to be taken. Actions and responses are recorded in a non-conformance report, and the customer is always informed. The finality of the complaint handling procedure is designed to always ensure that any identified issues cannot reoccur.

ORGANIC AND PURE FOR CULINARY EXCELLENCE

Besides our own strict quality standards, around 10 tonnes of our products are also certified organic.

The term ‘organic’ is one that is protected by law. As a result, there is mandatory monitoring in place for if you want to market products as being organic. And this applies for all links in the chain, from farmers and producers to distributors and retailers. Ganda produces and markets organic products, and is recognised as an organic producer for this purpose.

Ganda Ham contains no added flavourings, colourings, nitrates, nitrites, gluten, allergens, or preservatives – in other words, it’s a pure product! Ganda Ham is easy to digest and contains less than 10% fat, made up of mostly (54%) unsaturated fatty acids (85 mg cholesterol per 100 g). We also support healthy, creative cooking with Ganda Ham by collaborating with chefs to create innovative recipes. To that end, we also sponsor a number of cooking competitions.

TALK TO US